The difference between machined aluminum and die-cast aluminum

Dong Xing

aluminummanufacturerchina.com

2018-04-23 10:25:47

The heat dissipation and good appearance properties of aluminum alloys have surpassed the current plastic materials, and the weight that comes from their own weight is a plastic that cannot be replaced.

1, the material difference:

Die-cast aluminum alloys generally use ADC12 or ALsi9cu3, while aluminum cars generally use 6063 or 6061(6061 aluminum sheet on sale).

2, the difference between appearance:

Die-cast aluminum is equivalent to plastic injection molding process, can create any shape, the lamp shell above the general use of die-cast aluminum. However, the shape of the cross-section adopted by the car aluminum(Aluminum coil for car parts 3004) is less varied, such as the heat sink of the bulb lamp, the aluminum profile of the door and window.

3, thermal conductivity:

The general conductivity of die-cast aluminum is about 80-90W/M.K, while the thermal conductivity of car aluminum is about 180-190W/M.K.

4, cost:

The cost of die castings and car aluminum(Aluminum coil for car parts manufacturer) is relative, both calculated by weight and machining. Calculate costs based on real-time material prices and manual calculations. Relatively speaking, the cost of die-casting aluminum is higher, but the specific situation should be analyzed.

5, production efficiency:

Injection molding production efficiency is certainly higher, mass production, generally produce more than 1,000 a day, and the size is stable, the shrinkage rate is 0.5%. The composition of the car aluminum machining more, as the name suggests is the car aluminum, the efficiency is naturally lower.

6, Application:

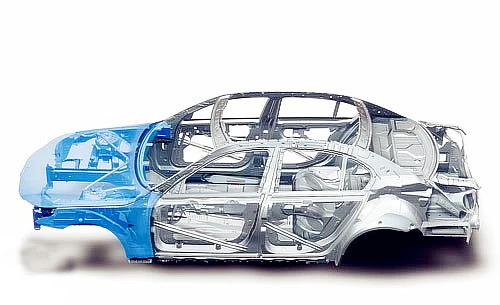

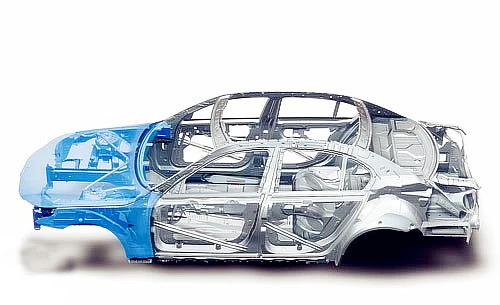

Die-cast aluminum is widely used in automobiles, street lamps, and the current mobile phone industry. Aluminum cars are widely used in downlights, ceiling lights, and doors and windows.

1, the material difference:

Die-cast aluminum alloys generally use ADC12 or ALsi9cu3, while aluminum cars generally use 6063 or 6061(6061 aluminum sheet on sale).

2, the difference between appearance:

Die-cast aluminum is equivalent to plastic injection molding process, can create any shape, the lamp shell above the general use of die-cast aluminum. However, the shape of the cross-section adopted by the car aluminum(Aluminum coil for car parts 3004) is less varied, such as the heat sink of the bulb lamp, the aluminum profile of the door and window.

The general conductivity of die-cast aluminum is about 80-90W/M.K, while the thermal conductivity of car aluminum is about 180-190W/M.K.

4, cost:

The cost of die castings and car aluminum(Aluminum coil for car parts manufacturer) is relative, both calculated by weight and machining. Calculate costs based on real-time material prices and manual calculations. Relatively speaking, the cost of die-casting aluminum is higher, but the specific situation should be analyzed.

5, production efficiency:

Injection molding production efficiency is certainly higher, mass production, generally produce more than 1,000 a day, and the size is stable, the shrinkage rate is 0.5%. The composition of the car aluminum machining more, as the name suggests is the car aluminum, the efficiency is naturally lower.

6, Application:

Die-cast aluminum is widely used in automobiles, street lamps, and the current mobile phone industry. Aluminum cars are widely used in downlights, ceiling lights, and doors and windows.