Why does aluminum plate play a bubble?

Dong Xing

aluminummanufacturerchina.com

2017-12-01 13:19:01

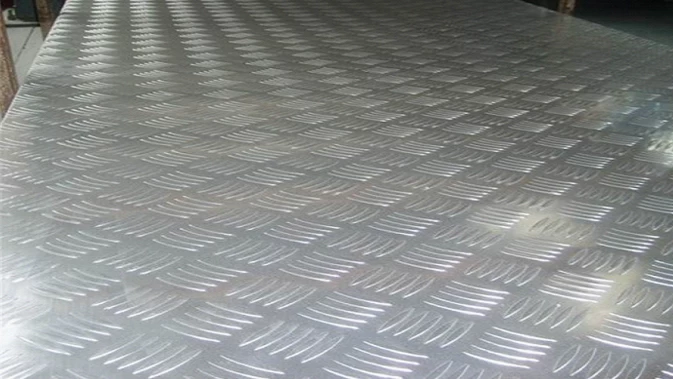

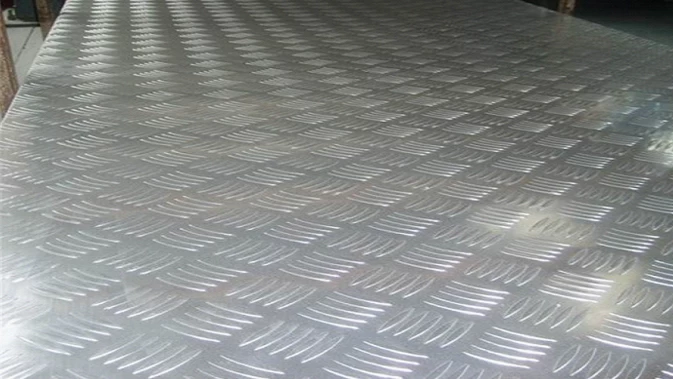

In the process of extrusion of the aluminum plate, there will be a surface or bubble. In the end, what is the cause of it? What method should be used to eliminate it? Now let me make a difference for you.

What is a bubble or a skin: a protruding bubble on the surface of the product is common in the head and tail, and the whole is called a bubble, and the broken skin is called. Harbin Dong Xing Aluminum Co., Ltd is a competent and reliable Aluminum sheet manufacturer china.

1. The reasons for the extrusion of aluminum plates to produce bubbles and peels

1. the wear of the extruding barrel and the extruding pad is very poor, and the size of the extruding tube and the extruding pad are not fit properly, and the diameter of the washer used is more than the allowable value.

2. the extruding barrel and the extruding pad are too dirty, with oil, water, graphite and so on.

3. the lubricating oil contains water.

4. ingot surface shovel groove too much, too deep, or have the ingot surface pores, trachoma, loose organization, oil etc.;

5. when the alloy is replaced, the inside of the cylinder is not cleaned.

6. the temperature of the extrusion cylinder and the temperature of the extruded ingot are too high.

7. ingot temperature and size exceed the allowable negative deviation.

8. ingot is too long, filling too fast, ingot temperature is not uniform, cause non drum filling, so the exhaust gas is not complete, or operation is improper, the exhaust process is not carried out.

9. die design is not reasonable, or cutting scrap improper diffluence hole and the guide hole in the residue was partly out of gas, extrusion gap in the surface into space.

Two. Elimination of bubble and peeling by extrusion of aluminum plate

Two. Elimination of bubble and peeling by extrusion of aluminum plate

1., reasonably design the fitting size of the extrusion cylinder and the extrusion gasket, check the tool size regularly, ensure that it meets the requirements, and the extrusion cylinder should be repaired in time, and the extrusion pad should not be overdone.

The surface of the 2. tools and ingot remains clean, smooth and dry. Harbin Dong Xing Aluminum Co., Ltd could provide you with Aluminum marine sheet.

3. completely clean the cylinder when replacing the alloy.

4. regular inspection of equipment and instruments to prevent excessive temperature and fast speed;

5. strictly implement the process regulations and various systems.

6. the design and manufacture of the tooling, the guide hole and the diverting hole are designed to be 1 degrees -3 degrees.

Strict operation, correct and complete exhaust residual shear.

Through expert answer questions, I believe you all have a deep understanding of the causes and elimination methods of aluminum plate extrusion bubble and skin. To avoid these problems in daily production, we can reduce losses and improve product yield.

What is a bubble or a skin: a protruding bubble on the surface of the product is common in the head and tail, and the whole is called a bubble, and the broken skin is called. Harbin Dong Xing Aluminum Co., Ltd is a competent and reliable Aluminum sheet manufacturer china.

1. The reasons for the extrusion of aluminum plates to produce bubbles and peels

1. the wear of the extruding barrel and the extruding pad is very poor, and the size of the extruding tube and the extruding pad are not fit properly, and the diameter of the washer used is more than the allowable value.

2. the extruding barrel and the extruding pad are too dirty, with oil, water, graphite and so on.

3. the lubricating oil contains water.

4. ingot surface shovel groove too much, too deep, or have the ingot surface pores, trachoma, loose organization, oil etc.;

5. when the alloy is replaced, the inside of the cylinder is not cleaned.

6. the temperature of the extrusion cylinder and the temperature of the extruded ingot are too high.

7. ingot temperature and size exceed the allowable negative deviation.

8. ingot is too long, filling too fast, ingot temperature is not uniform, cause non drum filling, so the exhaust gas is not complete, or operation is improper, the exhaust process is not carried out.

9. die design is not reasonable, or cutting scrap improper diffluence hole and the guide hole in the residue was partly out of gas, extrusion gap in the surface into space.

1., reasonably design the fitting size of the extrusion cylinder and the extrusion gasket, check the tool size regularly, ensure that it meets the requirements, and the extrusion cylinder should be repaired in time, and the extrusion pad should not be overdone.

The surface of the 2. tools and ingot remains clean, smooth and dry. Harbin Dong Xing Aluminum Co., Ltd could provide you with Aluminum marine sheet.

3. completely clean the cylinder when replacing the alloy.

4. regular inspection of equipment and instruments to prevent excessive temperature and fast speed;

5. strictly implement the process regulations and various systems.

6. the design and manufacture of the tooling, the guide hole and the diverting hole are designed to be 1 degrees -3 degrees.

Strict operation, correct and complete exhaust residual shear.

Through expert answer questions, I believe you all have a deep understanding of the causes and elimination methods of aluminum plate extrusion bubble and skin. To avoid these problems in daily production, we can reduce losses and improve product yield.

If you want to get more information about Harbin Dong Xing Aluminum Co., Ltd, please click Aluminum sheet wholesales.