Zunyi aluminum alloying to achieve zero breakthrough

Dong Xing

aluminummanufacturerchina.com

2018-02-27 11:30:00

February 3, Zunyi Aluminum Alloy Casting Phase III project all-aluminum project transformation - load test run a great success. Trial production of 3 furnaces on the day, the output of 48 tons, all product quality standards.

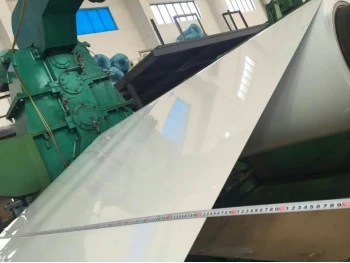

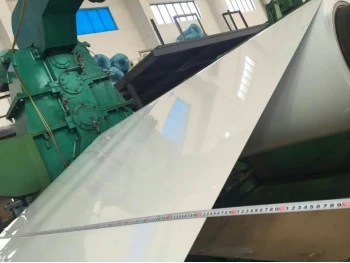

In order to save investment and reduce manufacturing costs, Zunyi Aluminum utilizes the original three-phase foundry idle production site to transform it into an aluminum alloy(3004-O aluminum plate) round rod production line. The project as the beginning of alloying Zunyi Aluminum Project, the company leaders attach great importance to instruct the casting plant (Alloying Working Group) and the parties on the company's third-phase foundry renovation project conducted several demonstrations, and finally determine the optimal transformation Program. After nearly half a year of intensive reconstruction, more than 10 projects such as the transformation of existing plant equipment and processes were completed. A new gas smelting furnace, aluminum ash treatment and dust collection system were completed to make the process layout more reasonable and meet the environmental protection requirements and achieve the expected goals And effect.

The implementation of this project is Zunyi Aluminum's strategy of implementing the alloying strategy of Alcoa Group, adjusting the structure, making up for the shortcomings and realizing the value-added of the products. The successful trial production of this project marks that Zunyi Aluminum Alloy has achieved zero breakthrough.

The implementation of this project is Zunyi Aluminum's strategy of implementing the alloying strategy of Alcoa Group, adjusting the structure, making up for the shortcomings and realizing the value-added of the products. The successful trial production of this project marks that Zunyi Aluminum Alloy has achieved zero breakthrough.

In order to save investment and reduce manufacturing costs, Zunyi Aluminum utilizes the original three-phase foundry idle production site to transform it into an aluminum alloy(3004-O aluminum plate) round rod production line. The project as the beginning of alloying Zunyi Aluminum Project, the company leaders attach great importance to instruct the casting plant (Alloying Working Group) and the parties on the company's third-phase foundry renovation project conducted several demonstrations, and finally determine the optimal transformation Program. After nearly half a year of intensive reconstruction, more than 10 projects such as the transformation of existing plant equipment and processes were completed. A new gas smelting furnace, aluminum ash treatment and dust collection system were completed to make the process layout more reasonable and meet the environmental protection requirements and achieve the expected goals And effect.