The 5083 reason is the amphoteric metal aluminum is what?

Dong Xing

aluminummanufacturerchina.com

2017-11-07 19:52:14

I don't know if everyone knows that the 5083 aluminum plate is amphoteric metal, that is to say, it can dissolve in alkali or dissolve in acid. Of course, if you are not too clear, you can come to know it with me:

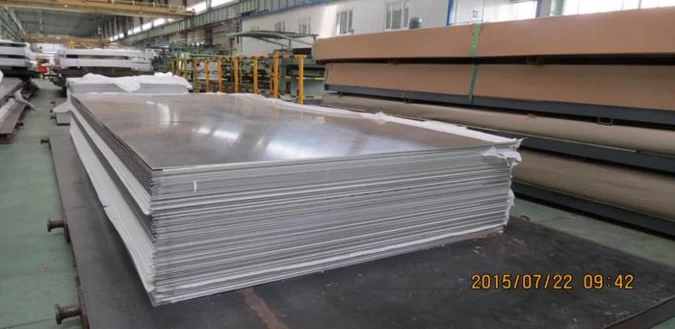

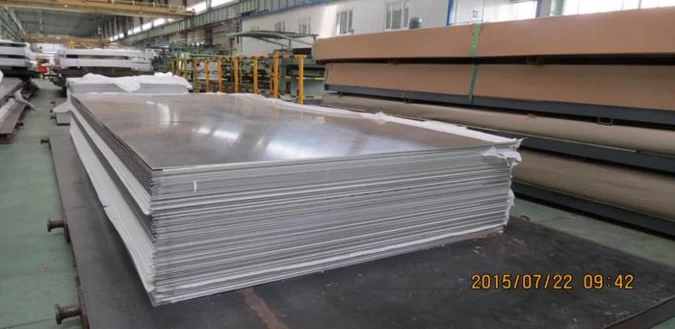

Zinc in dry air has little change. The humid air, the surface of zinc will generate basic zinc carbonate film. Zinc containing sulfur dioxide, hydrogen sulfide and marine atmosphere, zinc corrosion resistance is poor, 5083 aluminum plate, especially in high temperature and high humidity containing acid in the atmosphere, zinc coating is easy to be corroded. Harbin Dong Xing Aluminum Co., Ltd could provide you with 5083 aluminum sheet china.

The standard electrode potential of zinc is -0.76V. For steel substrate, zinc coating belongs to anodic coating, which is mainly used to prevent the corrosion of steel, and the protection performance of 5083 aluminum plate is closely related to the thickness of coating. After passivation, dyeing or coating light protection agent, zinc coating can significantly improve its protective and decorative properties.

See table is widely used in high voltage engineering pressure vessel and pipeline in high temperature or low temperature use galvanized steel composition, refers to the surface of metal, alloy or other material coated with a layer of zinc in surface treatment technology, such as the role of the rust of the beautiful.

See table is widely used in high voltage engineering pressure vessel and pipeline in high temperature or low temperature use galvanized steel composition, refers to the surface of metal, alloy or other material coated with a layer of zinc in surface treatment technology, such as the role of the rust of the beautiful.

Zinc dissolves in acid easily. Production process and casting equipment cold rolling 5083 aluminum slab continuous casting billet production process, cold rolling weathering steel continuous casting billet production process is: blast furnace ironmaking, converter smelting, refining, slab continuous casting, hot rolling mill.

Cold rolled steel composition of cold resistance of 5083 aluminum slab cracks in the side and casting conditions produce cracks in the side of 5083 aluminum is mainly used for container plate. Even in the environment with chemical erosion, so often require the use of special alloy steel to make it large thick walled tube container can be welded by the steel seamless tube production, or by forging method the production of manufacturing.

A method of producing the aluminum pipe can be traced back to the method devised by E Ahad in 1899 (the EhrhardtProeess in his name perforation and pull technology, a production of thick walled seamless pipe and the cylinder body is economy.

Zinc in dry air has little change. The humid air, the surface of zinc will generate basic zinc carbonate film. Zinc containing sulfur dioxide, hydrogen sulfide and marine atmosphere, zinc corrosion resistance is poor, 5083 aluminum plate, especially in high temperature and high humidity containing acid in the atmosphere, zinc coating is easy to be corroded. Harbin Dong Xing Aluminum Co., Ltd could provide you with 5083 aluminum sheet china.

The standard electrode potential of zinc is -0.76V. For steel substrate, zinc coating belongs to anodic coating, which is mainly used to prevent the corrosion of steel, and the protection performance of 5083 aluminum plate is closely related to the thickness of coating. After passivation, dyeing or coating light protection agent, zinc coating can significantly improve its protective and decorative properties.

Zinc dissolves in acid easily. Production process and casting equipment cold rolling 5083 aluminum slab continuous casting billet production process, cold rolling weathering steel continuous casting billet production process is: blast furnace ironmaking, converter smelting, refining, slab continuous casting, hot rolling mill.

Cold rolled steel composition of cold resistance of 5083 aluminum slab cracks in the side and casting conditions produce cracks in the side of 5083 aluminum is mainly used for container plate. Even in the environment with chemical erosion, so often require the use of special alloy steel to make it large thick walled tube container can be welded by the steel seamless tube production, or by forging method the production of manufacturing.

A method of producing the aluminum pipe can be traced back to the method devised by E Ahad in 1899 (the EhrhardtProeess in his name perforation and pull technology, a production of thick walled seamless pipe and the cylinder body is economy.

Up to now, this production method can be produced by ingot with a single weight of 26 tons or more. Harbin Dong Xing Aluminum Co., Ltd is a competent and reliable Aluminum board supplier.

Because this process is basically the same as the current pipe jacking process, it can be called the big pipe jacking production process. This method is still relatively advanced, and there are such factories in West Germany and Japan. Many users all over the world order this kind of products. Therefore, the production cost is greatly reduced.

If you want to get more information about Harbin Dong Xing Aluminum Co., Ltd, please click Aluminum sheet for boat 5083.