How to strengthen aluminum plate?

Dong Xing

aluminummanufacturerchina.com

2017-11-17 14:43:26

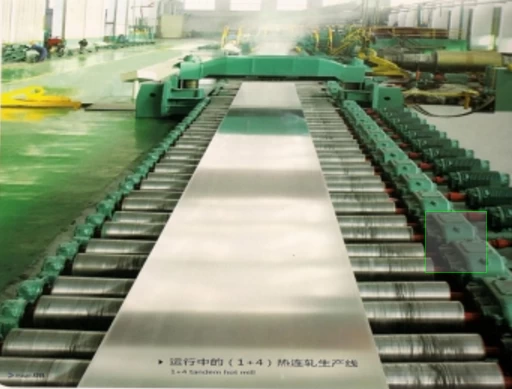

Aluminum plate believe that everyone is not strange, but we all want to let the strength can be strengthened, so today for everyone to solve this problem, we will introduce two kinds of methods to strengthen aluminum plate, I hope you can seriously record: Harbin Dong Xing Aluminum Co., Ltd is a competent and reliable Aluminum board supplier.

1. processing strengthening aluminum plate

Processing hardening is also called cold working hardening, that is, aluminum plate under the recrystallization temperature, cold deformation processing, such as forging, calendering, drawing, stretching, etc., when cold deformation, aluminum plate internal dislocation density increases, and intertwined with each other, and form a cellular structure, to prevent dislocation movement. The deformation of high dislocation tangles more severe, the greater the deformation resistance, the higher the strength.

1. processing strengthening aluminum plate

Processing hardening is also called cold working hardening, that is, aluminum plate under the recrystallization temperature, cold deformation processing, such as forging, calendering, drawing, stretching, etc., when cold deformation, aluminum plate internal dislocation density increases, and intertwined with each other, and form a cellular structure, to prevent dislocation movement. The deformation of high dislocation tangles more severe, the greater the deformation resistance, the higher the strength.

The degree of strengthening after cold deformation is different from the deformation degree, deformation temperature and the nature of the material itself. When the same material is cold deformed at the same temperature, the higher the deformation degree is, the higher the strength is and the lower the plasticity is. Harbin Dong Xing Aluminum Co., Ltd could provide you with 6061 aluminum sheet on sale.

2. solution strengthening aluminium plate

Adding some alloying elements into pure aluminum to form an infinite solid solution or a limited solid solution can not only obtain high strength, but also obtain excellent plasticity and outstanding pressure processing function. The most commonly used alloying elements in solid solution strengthening are copper, magnesium, manganese, zinc, silicon, nickel and other elements. Generally, the alloying of aluminum plate forms a limited solid solution, such as Al-Cu, Al-Mg, Al-Zn, Al-Si, Al-Mn and other two elements alloy, all of which form a limited solid solution, and have a larger limit solubility, which can play a greater role in solid solution strengthening.

By strengthening the aluminum plate, its hardness function will be significant progress, but its hardness can not always progress; when reaching the upper limit of hardness, regardless of the way, can not continue to advance the hardness of aluminum plate, can only choose the basis of higher hardness trademark.

In fact, the two methods introduced for you are relatively simple, it does not need too complex process can be solved, so you have to remember these two points. If you want to get more information about Harbin Dong Xing Aluminum Co., Ltd, please click Aluminum sheet wholesales.

2. solution strengthening aluminium plate

Adding some alloying elements into pure aluminum to form an infinite solid solution or a limited solid solution can not only obtain high strength, but also obtain excellent plasticity and outstanding pressure processing function. The most commonly used alloying elements in solid solution strengthening are copper, magnesium, manganese, zinc, silicon, nickel and other elements. Generally, the alloying of aluminum plate forms a limited solid solution, such as Al-Cu, Al-Mg, Al-Zn, Al-Si, Al-Mn and other two elements alloy, all of which form a limited solid solution, and have a larger limit solubility, which can play a greater role in solid solution strengthening.

By strengthening the aluminum plate, its hardness function will be significant progress, but its hardness can not always progress; when reaching the upper limit of hardness, regardless of the way, can not continue to advance the hardness of aluminum plate, can only choose the basis of higher hardness trademark.

In fact, the two methods introduced for you are relatively simple, it does not need too complex process can be solved, so you have to remember these two points. If you want to get more information about Harbin Dong Xing Aluminum Co., Ltd, please click Aluminum sheet wholesales.