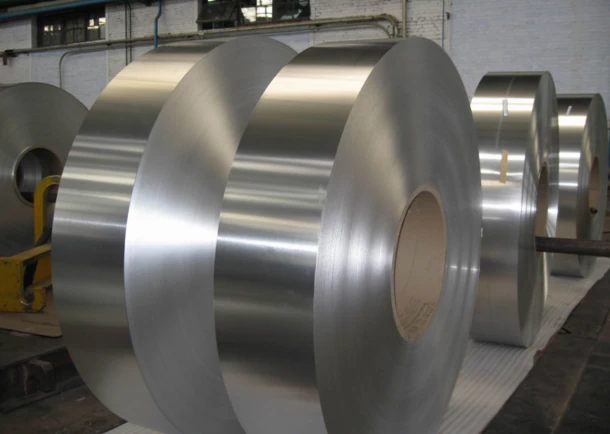

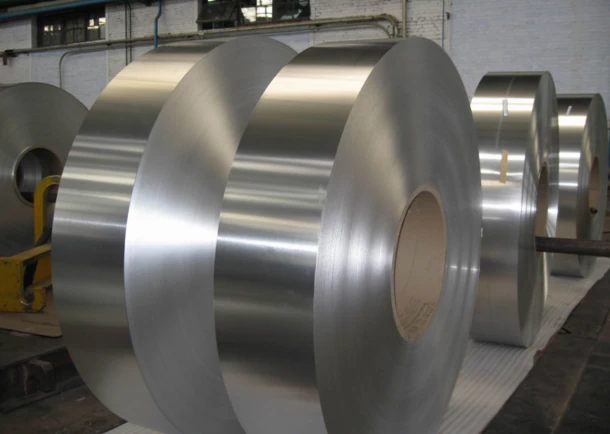

For you to solve the common problems of heat preservation aluminum coil

Dong Xing

aluminummanufacturerchina.com

2017-09-29 17:21:57

In the process of insulation aluminum coil may encounter some problems, these problems have troubled a lot of friends, today, for two of the more common problems, for everyone to answer.

First: insulation aluminum coil processing requirements after forming a little bit of deformation, why previously bought in the market of insulation aluminum coil is in the processing of a day or two days suddenly deformation?

Answer: the perfect pre stretching eliminates internal stress treatment, eliminates the internal stress completely, and does not warp, crack and deform when it is processed and stressed. Harbin Dong Xing Aluminum Co., Ltd is a competent and reliable Aluminum cladding coil manufacturer china.

Second: we are in the process of insulation aluminum mold manufacturing, one of the headaches is that after the completion of most of the processing process, suddenly found on the polished surface of sand holes or unknown miscellaneous particles appear, and now the workpiece scrapped. Harbin Dong Xing Aluminum Co., Ltd could provide you with Aluminum coating coil 1100.

Second: we are in the process of insulation aluminum mold manufacturing, one of the headaches is that after the completion of most of the processing process, suddenly found on the polished surface of sand holes or unknown miscellaneous particles appear, and now the workpiece scrapped. Harbin Dong Xing Aluminum Co., Ltd could provide you with Aluminum coating coil 1100.

Answer: to ensure the grain refinement process unique, all through the aerospace use ultrasonic inspection Aluminum Alloy products, sand hole, stripes, bubbles and impurities. Thermal treatment technology of aluminum products in the volume of excellence, 300mm thickness (or diameter), strength and hardness can be consistent. The entire production process control computer rarely, human error, the production of different batches can also guarantee the performance.

Of course, the insulation aluminum coil in the process must not only have these two problems, which requires everyone in the usual work, see more, ask more and more study and summary, to avoid problems, even if there is a problem, can be solved soon.

First: insulation aluminum coil processing requirements after forming a little bit of deformation, why previously bought in the market of insulation aluminum coil is in the processing of a day or two days suddenly deformation?

Answer: the perfect pre stretching eliminates internal stress treatment, eliminates the internal stress completely, and does not warp, crack and deform when it is processed and stressed. Harbin Dong Xing Aluminum Co., Ltd is a competent and reliable Aluminum cladding coil manufacturer china.

Answer: to ensure the grain refinement process unique, all through the aerospace use ultrasonic inspection Aluminum Alloy products, sand hole, stripes, bubbles and impurities. Thermal treatment technology of aluminum products in the volume of excellence, 300mm thickness (or diameter), strength and hardness can be consistent. The entire production process control computer rarely, human error, the production of different batches can also guarantee the performance.

Of course, the insulation aluminum coil in the process must not only have these two problems, which requires everyone in the usual work, see more, ask more and more study and summary, to avoid problems, even if there is a problem, can be solved soon.

If you want to get more information about Harbin Dong Xing Aluminum Co., Ltd, please click 3003 aluminum coil on sale.