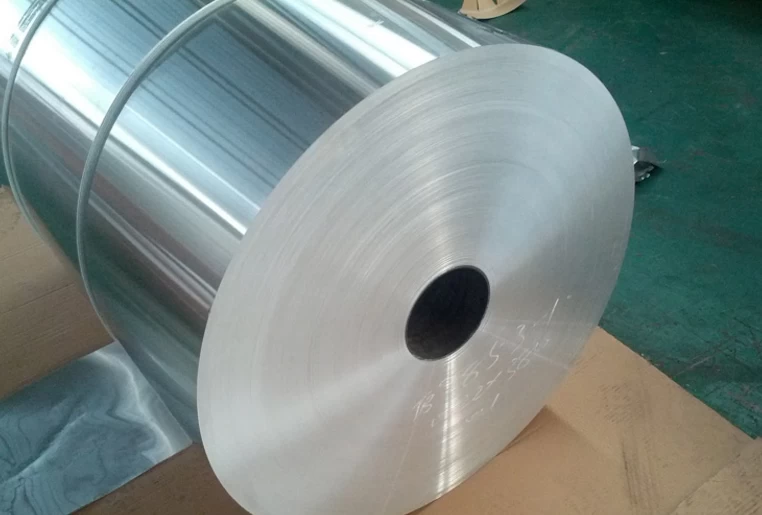

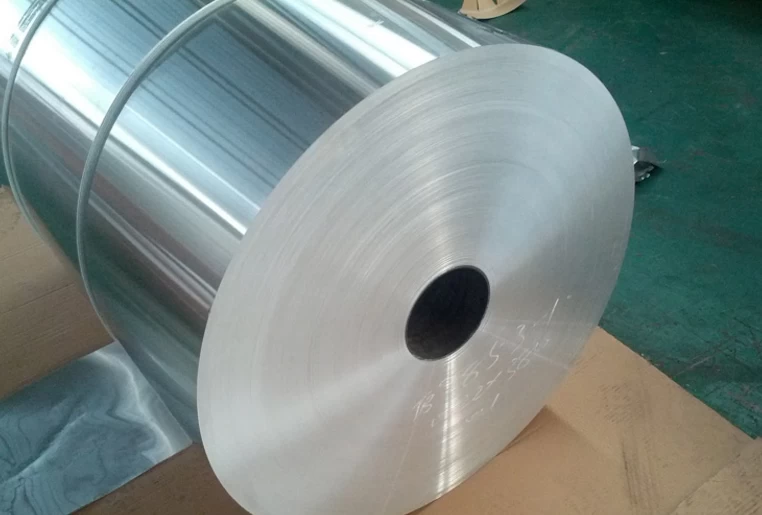

Surface treatment of heat preservation aluminum coil

Dong Xing

aluminummanufacturerchina.com

2017-10-26 14:36:40

All the products need to go through rigorous process, in order to prepare high-quality products, insulation aluminum coil is so. It needs a variety of production processing procedures, to ensure that users of the rest assured, to buy the rest assured.

The insulation aluminum coil surface treatment can be divided into: anodic oxidation and electrostatic spraying. Harbin Dong Xing Aluminum Co., Ltd is a competent and reliable Aluminum cladding coil manufacturer china.

Aluminum Alloy volume anodic oxidation film in general more than 12 mu, only the bronze color and white two colors, monotonous, is not caused by the production technology, but because the heat insulation aluminum coil is not by a lot of chemical composition, have small differences, coupled with the oxidation of factors of electrolysis bath and current density are not completely so much as, after the oxidation of color difference leaflets may not obvious, if all together is very obvious. So the insulation of aluminum curtain wall roll roll surface treatment, should not be used to anodic oxidation.

Another roll of insulating aluminum surface treatment method is spraying and electrostatic spraying spraying for spraying powder and liquid. Powder coating material for polyurethane and poly resin, epoxy resin and other raw materials expansion with high color retention pigment, powder spraying foam can be dozens of different colors.

Another roll of insulating aluminum surface treatment method is spraying and electrostatic spraying spraying for spraying powder and liquid. Powder coating material for polyurethane and poly resin, epoxy resin and other raw materials expansion with high color retention pigment, powder spraying foam can be dozens of different colors.

Different processing methods, the product is not the same, which requires customers to buy insulation aluminum coil, but also must be selected according to their own use requirements.

Aluminum Alloy volume anodic oxidation film in general more than 12 mu, only the bronze color and white two colors, monotonous, is not caused by the production technology, but because the heat insulation aluminum coil is not by a lot of chemical composition, have small differences, coupled with the oxidation of factors of electrolysis bath and current density are not completely so much as, after the oxidation of color difference leaflets may not obvious, if all together is very obvious. So the insulation of aluminum curtain wall roll roll surface treatment, should not be used to anodic oxidation.

The foam spraying powder collision resistance, abrasion resistance, impact 50 kilograms, insulation coating aluminum coil deformation, no crack, no off layer intact, resistance to dilute acid and mortar. Harbin Dong Xing Aluminum Co., Ltd could provide you with 3104-O aluminum lamp coil.

Different processing methods, the product is not the same, which requires customers to buy insulation aluminum coil, but also must be selected according to their own use requirements.

If you want to get more information about Harbin Dong Xing Aluminum Co., Ltd, please click 3104 aluminum lamp coil on sale.