How to do the pre treatment work of high quality aluminum plate

- Author:Dong Xing

- Source:aluminummanufacturerchina.com

- Release on:2018-01-05

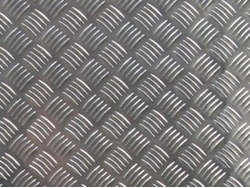

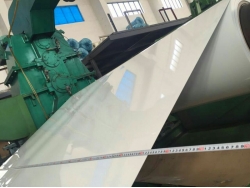

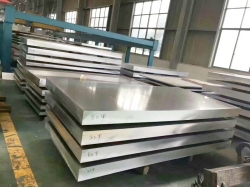

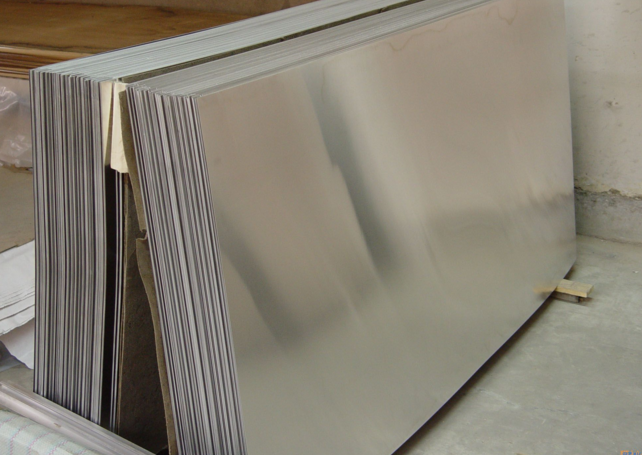

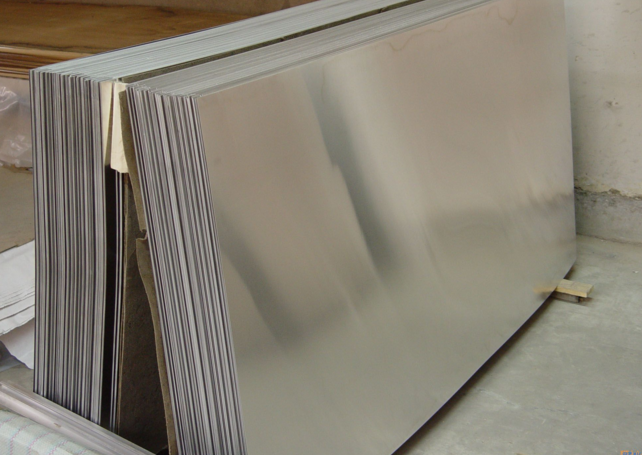

Aluminum plate with excellent performance is not only widely used, but also of better quality. The pretreatment of high quality aluminum sheet plays a very important role in improving the performance of aluminum sheet. Harbin Dong Xing Aluminum Co., Ltd is a competent and reliable Aluminum sheet wholesales.

Aluminum products are widely used in automotive, construction and other industries. Improving the quality of aluminum products is the fundamental reason for the survival of enterprises. Aluminum materials are very unstable in the air, and easy to generate oxide films which are difficult to identify with the naked eye.

Aluminum products are widely used in automotive, construction and other industries. Improving the quality of aluminum products is the fundamental reason for the survival of enterprises. Aluminum materials are very unstable in the air, and easy to generate oxide films which are difficult to identify with the naked eye.

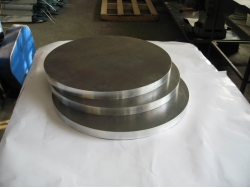

Because the aluminum processing technology of different methods, such as casting, or by pressing plate and direct shear, or mechanical fine processing, or by different molding process after heat treatment or welding, the workpiece surface will appear in different states, dirt or traces of different degrees, so before the process must be based on the actual situation of processing process of workpiece surface before. Harbin Dong Xing Aluminum Co., Ltd could provide you with 6061 aluminum sheet on sale.

Need to pay attention to the pretreatment process, casting molding are not all surfaces after machining, without surface machining for casting process of forming a thick oxide layer, some also with sand, this should be the first to use the method of blasting machine or remove the parts of the original film, or by alkali after washing and processing, the only way to removing the original oxide layer net unprocessed parts, but also can avoid the machining position tolerance change.

Need to pay attention to the pretreatment process, casting molding are not all surfaces after machining, without surface machining for casting process of forming a thick oxide layer, some also with sand, this should be the first to use the method of blasting machine or remove the parts of the original film, or by alkali after washing and processing, the only way to removing the original oxide layer net unprocessed parts, but also can avoid the machining position tolerance change.

Fine machining parts need attention in the pretreatment process of problem: fine processing although the natural oxide film surface was first generated, easy to remove, but heavy greasy, especially in and around the holes, the workpiece must be preceded by organic solvent cleaning, if the direct use of caustic wash not only heavy to oily cleaning, alkali the corrosion and fine processing surface to bear the long time, the results will affect the workpiece surface roughness and tolerance, may eventually become waste.

Fine machining parts need attention in the pretreatment process of problem: fine processing although the natural oxide film surface was first generated, easy to remove, but heavy greasy, especially in and around the holes, the workpiece must be preceded by organic solvent cleaning, if the direct use of caustic wash not only heavy to oily cleaning, alkali the corrosion and fine processing surface to bear the long time, the results will affect the workpiece surface roughness and tolerance, may eventually become waste.

If you want to get more information about Harbin Dong Xing Aluminum Co., Ltd, please click Aluminum marine sheet.