Method for repairing flatness of heat preservation aluminium coil

- Author:Dong Xing

- Source:aluminummanufacturerchina.com

- Release on:2017-09-18

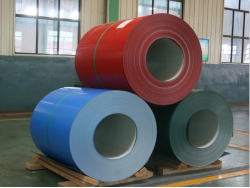

Because a lot of industry in the application of insulating aluminum coil, flatness of the higher, so manufacturers of aluminum coil insulation of the production of the control is strict. The flatness of the aluminum coil insulation repair mainly use the repair mode, offline finishing, online finishing in three ways to achieve the purpose.

1, use the die repair to improve the smoothness of the insulation aluminum coil

Repair mode is both at home and abroad for the smoothness of the solution of bad extrusion materials commonly used, insulation plane gap aluminum coil is bad, and the mold velocity is not uniform, the size or the angle change of the diversion channel, or change the work with the length to effectively adjust the metal flow, so that the uniform velocity, eliminate defects the plane gap is bad. Harbin Dong Xing Aluminum Co., Ltd could provide you with Aluminum coated coil 3004-O.

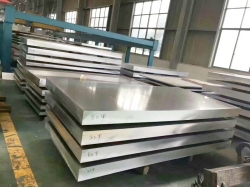

2. Use the off-line finishing to correct the flatness of the heat preservation aluminum coil

2. Use the off-line finishing to correct the flatness of the heat preservation aluminum coil

According to the specific characteristics of insulation aluminum coil flatness outoftolerance, and pieces of the rational allocation of offline finishing machine, then use a flat products ultra poor of roller, by constantly adjust the height and position of roll film, to be the only plane of the aluminum coil insulation degree after passing the height and position of the fixed roller sheet then, the product of the batch off-line finishes. Harbin Dong Xing Aluminum Co., Ltd is a competent and reliable Aluminum PVDF coated coil manufacturer.

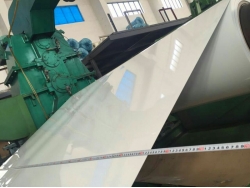

3, the on-line finishing is used to correct the flatness of the heat preservation aluminum coil

Online finishing is according to the principle of offline finishing, installation of bearing and roll film based on the original press outlet guide device on the height and position of roller sheet to change the deformation of the aluminum coil insulation pressure to produce a certain amount of insulation, let aluminum coil flatness control within a reasonable range, so as to achieve the purpose of online finishes.

1, use the die repair to improve the smoothness of the insulation aluminum coil

Repair mode is both at home and abroad for the smoothness of the solution of bad extrusion materials commonly used, insulation plane gap aluminum coil is bad, and the mold velocity is not uniform, the size or the angle change of the diversion channel, or change the work with the length to effectively adjust the metal flow, so that the uniform velocity, eliminate defects the plane gap is bad. Harbin Dong Xing Aluminum Co., Ltd could provide you with Aluminum coated coil 3004-O.

According to the specific characteristics of insulation aluminum coil flatness outoftolerance, and pieces of the rational allocation of offline finishing machine, then use a flat products ultra poor of roller, by constantly adjust the height and position of roll film, to be the only plane of the aluminum coil insulation degree after passing the height and position of the fixed roller sheet then, the product of the batch off-line finishes. Harbin Dong Xing Aluminum Co., Ltd is a competent and reliable Aluminum PVDF coated coil manufacturer.

3, the on-line finishing is used to correct the flatness of the heat preservation aluminum coil

Online finishing is according to the principle of offline finishing, installation of bearing and roll film based on the original press outlet guide device on the height and position of roller sheet to change the deformation of the aluminum coil insulation pressure to produce a certain amount of insulation, let aluminum coil flatness control within a reasonable range, so as to achieve the purpose of online finishes.

If you want to get more information about Harbin Dong Xing Aluminum Co., Ltd, please click Aluminum coated coil 1100-O.